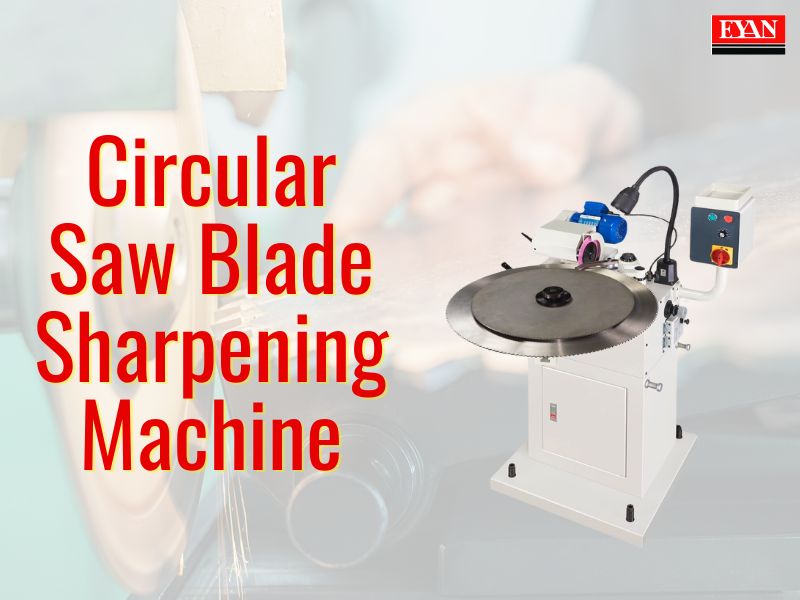

Maximizing the Lifespan of Your Circular Saw Blade Sharpener: A Comprehensive Guide by Eyan Machine Tools Co., Ltd

Investing in a Circular Saw Blade Sharpener is a wise decision for any steel mill or tube manufacturer. As a distinguished leader in the industry, Eyan Machine Tools Co., Ltd, headquartered in Taichung, Taiwan, has been manufacturing a variety of saw blade sharpening machines, circular knives grinders, and End Mill Sharpeners for over 20 years. Eyan conducts business worldwide, maintaining strong relationships with customers and having agents in key regions, including Japan, U.S.A., and Thailand.

Expertise in Saw Blade Sharpener Manufacturing

Eyan Machine Tools specializes in developing state-of-the-art saw blade sharpeners, constantly designing and renovating machines to be user-friendly and highly effective. Over the years, Eyan has introduced new models to meet customer requirements, positioning itself as the only supplier globally to offer CNC machines that sharpen saw blades with diameters up to 2500mm.

Commitment to Quality and User-Friendliness

"Stable quality and user-friendly" define Eyan's philosophy. The company's expertise allows for strict quality control at every stage of production. Upon delivering a machine, Eyan provides on-site training if needed, ensuring that customers can harness the full capabilities of their equipment.

Responsive Support and Immediate Repairs

In the event of machine issues, Eyan boasts a professional team capable of immediate repairs within a short timeframe. This commitment minimizes any potential delays in customer production, showcasing Eyan's dedication to responsive customer support.

Versatility Across Industries

Eyan's machines find applications across diverse industries, including automobile, electronics, paper, plastic, foods, sports equipment, bicycles, and more. The machines cater to the sharpening needs of circular saw blades, circular knives, slitter knives, end mills, and drills.

International Recognition and Market Leadership

Eyan's perfect performance in technology and equipment has positioned it as the leader in this profession. The company has successfully propelled its brand into the international market, earning recognition for providing high-efficiency machines, outstanding quality of results, and, importantly, long service life.

Guide to Protecting Your Eyan Circular Saw Blade Sharpener

Now, let's delve into a comprehensive guide on how to protect your Eyan Circular Saw Blade Sharpener from premature aging. By following these steps, you ensure that your investment remains reliable and efficient throughout its lifespan.

1. Proper Installation and Setup

Begin by ensuring that your Eyan machine is installed on a stable and level surface. Follow the manufacturer's guidelines for setup meticulously to prevent unnecessary wear and tear. A stable foundation is the first step toward a long-lasting Circular Saw Blade Sharpener, and Eyan is committed to helping you achieve this.

2. Regular Cleaning and Maintenance

Sawdust, debris, and metal shavings can accumulate during use and compromise the efficiency of your Eyan machine. Regularly clean the blade sharpener using a brush or compressed air to prevent build-up. Trust Eyan's expertise in providing reliable and efficient solutions for maintaining your equipment.

3. Lubrication

Moving parts of the machine require proper lubrication. Refer to the manufacturer's recommendations for the type and frequency of lubrication needed. Pay special attention to blade adjustment mechanisms to ensure they operate smoothly, contributing to the overall longevity of your Eyan machine.

4. Blade Inspection

Regularly inspect the circular saw blades for signs of damage, dullness, or irregularities. Replace or sharpen blades as needed to prevent excessive strain on your Eyan machine. A well-maintained blade not only improves performance but also reduces stress on the sharpening mechanism, showcasing Eyan's commitment to precision.

5. Appropriate Use

Use the machine within its specified capacities and limitations. Avoid overloading the machine with excessively dull or damaged blades. Following Eyan's recommended usage guidelines prevents unnecessary strain on the motor and other critical components.

6. Safety Practices

Prioritize safety. Always follow safety guidelines and use appropriate personal protective equipment (PPE). Ensure that your Eyan machine's safety features are functional and well-maintained. A safe operating environment contributes to the overall health of the machine.

7. Cooling Systems

If your Eyan Circular Saw Blade Sharpener has a cooling system, ensure it is working correctly. Overheating can lead to premature wear, so proper cooling is crucial during extended use. Regularly check and clean the cooling system to maintain optimal performance, reflecting Eyan's commitment to advanced technology.

8. Storage

When not in use, store the machine in a clean and dry environment. Covering the machine protects it from dust and moisture, preventing corrosion and damage to sensitive components. Eyan understands the importance of proper storage in preserving the integrity of your equipment.

9. Regular Calibration

Periodically check and calibrate the machine to maintain accuracy in sharpening. Ensure that the settings are aligned correctly for optimal performance. Regular calibration, with Eyan's precision engineering, contributes to consistent and precise sharpening results.

10. Training and Education

Proper training is key to ensuring that operators use and care for the machine correctly. Eyan encourages a culture of responsibility to report any issues promptly. Our commitment to education underscores our dedication to empowering users with the knowledge to maximize the potential of their Eyan equipment.

11. Scheduled Inspections

Establish a routine schedule for comprehensive inspections and maintenance. Regularly check all components for signs of wear and address any identified issues promptly to prevent further damage. Eyan's proactive approach to maintenance ensures the longevity of your investment.

12. Keep a Log

Maintain a detailed log of maintenance activities, inspections, and any issues addressed. This log, a testament to Eyan's commitment to transparency, serves as a valuable reference for future maintenance and troubleshooting, helping you stay ahead of potential problems.

By adopting these practices with Eyan, a trusted name in the industry, you can significantly extend the lifespan of your Circular Saw Blade Sharpener, ensuring that it remains a reliable and efficient tool for all your cutting needs.