Why Your Factory Needs an Industrial Circular Saw Blade Sharpening Machine

Introduction

In modern manufacturing environments, where quality, speed, and precision define competitiveness, tool maintenance is not optional—it’s strategic. Among cutting tools, circular saw blades play a vital role across industries including metalworking, packaging, woodworking, plastics, paper converting, and food processing. However, even the highest-grade saw blades dull over time. This is why having an industrial circular saw blade sharpening machine in-house can significantly elevate your productivity, reduce costs, and give your operation a critical edge.

What Is an Industrial Circular Saw Blade Sharpening Machine?

An industrial sharpening machine is designed specifically for restoring the sharpness and geometry of circular blades and slitter knives used in high-demand, high-volume operations. Unlike consumer-grade or manual sharpening tools, these machines are engineered for:

- Precision grinding down to ±0.005 mm

- Wide blade compatibility, typically from ø65 mm to ø500 mm

- Full automation with CNC programming and servo-driven movements

- Consistent sharpening angles for optimal cutting performance

- Oil cooling and recycling systems for durability and eco-friendliness

- Noise-reduction designs for factory environments

Whether it’s HSS (High-Speed Steel) or carbide-tipped circular blades, these machines ensure that every edge is restored to its original sharpness—safely, accurately, and efficiently.

Why You Should Invest in One

1. Lower Blade Replacement Costs

A high-quality sharpener extends blade life dramatically by enabling multiple sharpening cycles without degrading performance. This saves costs over time, especially for expensive or large-diameter industrial blades.

2. Greater Cutting Precision and Product Consistency

Dull blades cause inconsistencies in cut quality. A sharpening machine ensures that every tooth is ground to the correct angle and depth, which is critical for industries like paper, electronics, and packaging where precision matters.

3. In-House Control & Faster Turnaround

No more waiting days for external sharpening services. With an in-house sharpener, you can service blades immediately, reduce downtime, and maintain production flow.

4. Cleaner Cuts, Less Waste

Sharper blades result in cleaner edges, less chipping, and reduced material waste. This contributes to both higher product quality and a more sustainable operation.

5. Support for ESG Goals

Modern machines feature enclosed dust systems, noise reduction, energy-efficient motors, and oil recycling— contributing to a safer, cleaner, and greener factory.

Key Features to Look For

When choosing an industrial circular saw blade sharpening machine, look for these important features:

| Feature | Why It Matters |

|---|---|

| CNC Control System | Enables programmable precision and repeatability for all types of blade profiles |

| Servo-Driven Movement | Ensures smooth, accurate positioning and energy efficiency |

| Variable Speed Control | Allows you to adjust grinding speed for different materials and blade types |

| Grinding Range | Machines with a wide range (e.g., ø65 mm to ø500 mm) support more applications |

| Rotary Pneumatic Cylinder | Optional feature that enables fast tool changes and minimizes downtime |

| Noise-Reduction Enclosure | Improves operator safety and reduces workplace noise |

| Oil Recycling System | Filters and reuses oil, minimizing waste and supporting environmental compliance |

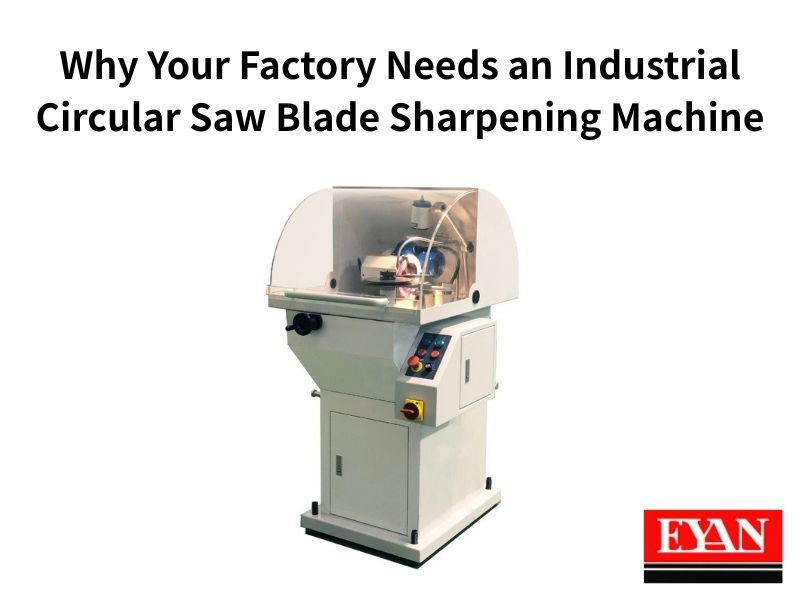

Eyan’s S300C: Compact and Precise for Industrial Sharpening

The S300C Circular Saw Blade Sharpener is designed for industrial users who need reliable and accurate blade maintenance. With a grinding range of ø65 mm to ø300 mm, it’s ideal for sharpening circular saw blades used in tube cutting and general metal processing.

Key Benefits:

- Precision Grinding: Delivers high sharpening accuracy to restore cutting performance

- Cooling System: Prevents overheating and blade burn during grinding

- Enclosed Splash Guard: Reduces noise and dust, ensuring a cleaner workspace

- Stable Machine Base: Improves grinding consistency and accuracy

- User-Friendly Design: Easy adjustment of tooth angles, depth, and pitch

- Variable Speed Control: Adjust grinding speed easily without changing pulleys

Built with FCD-45 cast iron and SKD II alloy steel parts, the S300C is both durable and efficient— perfect for high-use industrial environments.

Conclusion

A dull blade costs more than just time—it can compromise product quality, increase material waste, and affect your entire production line. Investing in a reliable, industrial-grade circular saw blade sharpening machine gives you greater control, better results, and long-term savings.

If your factory values precision, speed, and sustainability, an in-house sharpening solution like the S300C is a smart investment.

Contact Eyan Machine Tools today to learn more or schedule a demo with our technical team.